When

is Grounding Your Yacht Ever Good?

Well

it’s not when you have lost your way in the fog and end up on the rocks,

that’s for sure.

Where

it does come into it’s own is when it is providing the best earth possible to

your electronics and in particular, your Single Sideband Radio.

If

you are planning to venture further than the usual trip across the English

Channel or indeed 30Nm or more offshore, and want to remain in contact, then you

will probably be looking at installing a long range High Frequency (HF) radio,

more commonly known as a Single Sideband (SSB) Radio for your communications.

You

could be looking at other more modern (and expensive!) options such as Inmarsat,

Satellite Telephone or indeed Mini-M after maybe having had a poor experience

with SSB radios in the past, but look out, you will be paying through the nose

for any pictures and weather forecasts you receive. SSB radios are not an

antiquated form of communication by any stretch of the imagination!

It

may be that you already have an existing SSB radio fitted, but the installation

fundamentals have just been overlooked and because of your resultant lack of

reception or poor quality signal, you may have given up and are looking at

alternatives.

Well

…… not so fast

A

good SSB installation will give you very good weather forecasts, reports, faxes,

routing, worldwide communication and radio contact with various yachting safety

networks all for free; and with the easy addition of a special “PACTOR”

modem, you can even get Internet browsing and email at a very affordable level!

You

might be installing a long range radio system from scratch, maybe with a view to

break free from your regular life and sail your dream across the Atlantic to the

Caribbean. Good examples of this are the 200 or so yachts that annually compete

in the A.R.C. (Atlantic Rally for Cruisers). A race across the Atlantic, from

Gran Canaria to St Lucia.

These

yachts have a daily reporting schedule whilst in transit, where they check-in

with their positions (and quite often amusing anecdotes) whilst crossing the

ocean in company and relative safety. They utilise their SSB’s to receive

weather information to enable them to choose the best route and avoid any nasty

surprises. Then once they are safely ensconced in the Caribbean they may check

in daily to weather and safety radio nets so they can safely cruise the

Caribbean Island chain and keep in touch at the same time.

Well,

you would have chosen a high quality transmitter / receiver unit such as the

ICOM IC-M710 with an ICOM AT-130 automatic tuner unit. You will have chosen an

aerial option (whip, backstay or halyard), a separate dedicated radio battery

and charger, and a way of getting the whole system earthed into the ocean such

as a grounding plate like the “WonderBar” or “Dynaplate.

Let’s

start under the water. For a good earth (assuming you are not steel hulled) you

will have to haul the boat to install a grounding plate.

It should be installed as deep as possible and as close to the centreline

as possible to ensure it’s always covered with water, and when you install it,

it should “hang off” of the boat so that the plate has water on all of

it’s faces to maximise it’s earthing area. Do not bond it to the hull using

5200 between the plate and the hull or you will regret it!

If

you short cut the grounding process by earthing to the engine block or a keel

bolt, you may as well throw the whole lot overboard as the “noise” and

interference you will get, will make the radio annoying and maybe unusable.

On our boat (a 61ft

Oyster sailing yacht called “Talisman”), we chose the Mark VII Wonderbar

(21” long x 7” wide x ½” thick) as a grounding plate. This comes with 5

holes, 5 countersunk screws and 5 seals called “WonderSeals” which keep the

water out of the boat if installed properly!

We basically threw the screws that it came with away, and

invested in a 6ft long length of Bronze Silicon threaded stud (the same diameter

as the holes in the plate) and cut it into 5 equal 14” lengths using a band

saw, cleaning the swarf and threads afterwards.

Bronze

Silicon stud is the best metal for conduction of “earth” and although it’s

expensive, it’s not much in the grand scheme of things.

We

also bought an additional 5 “WonderSeals” to complete the install of the

plate so that we have a seal on the inside and the outside of the hull. A bit

over the top maybe but it’s a good, easy and cheap way to make sure it

doesn’t leak.

We have just sailed

over 5000Nm in 4 months with this install and it hasn’t leaked a drop and the

quality of our signal both sending and receiving is fantastic.

The

longer studs and suspended grounding plate basically enables us to dive on the

boat at any stage and remove the plate to clean it. That way we don’t have to

haul and we keep our radio performance in peak condition. The plate does tend to

clean itself when you transmit on the radio but if you don’t use it for any

length of time, it soon clogs up.

It

is quite common for people to dive on their yachts in the tropics to attempt to

keep their hull clean, unless they have a very good antifoul (such as Micron 44

or 66) suitable for that type of water and usage.

The antifoul you choose to paint your yacht with is another important point to bear in mind before you attempt to sail to warmer climbs. Unless (of course) you want to haul and re-paint when you get there. Mind you, scrubbing your hull by hand underwater is a good way to combine a swim with a keep fit class!

Next,

we have to carefully and accurately drill the holes in the hull to fix and

connect the plate to the “inside world” of your yacht. On the waterside of

the hull around the holes, it is important to remove any antifoul equal or

greater in area to the footprints of the “WonderSeals” so that they can

adhere to the hull in a strong and watertight way.

You

can antifoul the area again after the install but the seals must have a good

solid surface to stick to. A Dremmel tool is good for this. The area should

obviously be sanded flat before fixing to.

Carefully

drill Holes to suit the grounding plate. Remove the bilge paint and antifoul

from both inside and outside to ensure a good bond to sound surfaces. It’s

normally easiest to drill from the outside. Have a vacuum cleaner sucking from

inside the boat to catch the mess and stop debris clogging up your limber holes

in your bilge.

Notice

that the antifoul has been stripped back ready to receive the seals and

adhesive. The seals have a donut recess in them to take the sealant. Placed like

this, it allows you to add the sealant with minimal mess, then just push them up

against the hull and tighten the nuts on both sides. Don’t forget to run some

5200 up the holes in the hull and around the threads of the studs.

Add

the marine sealant (Use 3M 5200 – permanent bond for best results) to the

seals both inside and outside and tighten the nuts up on both sides allowing

24hrs to “go off” before fitting the plate and copper foil strip inside the

boat.

The

5 studs and seals are now in place ready to take the plate outside and copper

earthing foil inside after the sealant has had time to go off.

Mineral Spirits can

be used effectively to remove excess sealant and to clean the threads, and your

tools. Don’t go too mad though. It doesn’t matter that you can see some

sealant around your seals and studs. Just a light wipe is all I would suggest. I

always worry that it will affect the “setting” of the sealant if you use too

much.

Outside,

the finished seals are ready to take a couple of coats of antifoul. Do not paint

the studs.

And

the finished thing, ready to take the WonderBar. Note the double nuts to lock

the studs in place.

The

finished product. The manufacturer’s countersunk screws are replaced with

14” long Bronze Silicon studs (length depends on the thickness of your hull)

so that the plate can be removed with ease for cleaning. Also the plate is

suspended from the hull to maximise the surface area for grounding purposes.

This

plate is not new and has been re-used over the past 2 years and still going

strong. Muriatic acid (The old name for hydrochloric

acid (HCl)) is

great for cleaning it up like new but wear goggles and gloves, as it’s very

corrosive. The plate does tend to clean itself when you transmit on the radio.

The ends of each stud were drilled through and split pins

inserted to stop the final bolts from dropping off.

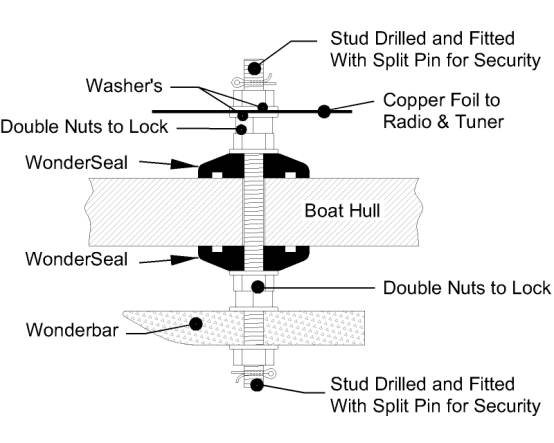

Sectional

Diagram Illustrating the Installation of the Grounding Plate, seals and studs

Copper

foil is run to every stud to maximise the use and area of the grounding plate.

This plate is purely for the SSB radio. There is a second smaller grounding

plate for the electronics, which massively reduces radio interference and noise.

Why

foil?

Round wires create inductive reactance at radio frequencies, and are not

effective as a good grounding conveyance. Use 2 or 3 inch wide, 3 mil copper

foil (available at most marine electronic stores) to achieve a good seawater

ground.

One

end of the copper foil is connected directly to the back of the radio unit

itself. Fold the foil 2-3 times being careful not to cut yourself (it’s very

sharp) and drill it through so you have a good connection. Do not be tempted to

earth anything else to this foil.

It

is VERY important that you do not attempt to connect the radio or tuner or any

part of your radio system to earth using a wire no matter how thick it is.

Copper foil is all you should use throughout; as wire develops a resistance to

earth and will severely affect your whole system.

The

other end of the copper foil is connected directly to the automatic tuner

(mounted in the lazarette in this case) and all of the electrical connections

are covered with a Urethane Seal Coat aerosol paint to reduce corrosion as much

as possible.

Polyurethane

Non Conductive Seal Coat to protect connections from the elements.

In

between the radio and the grounding plate we installed a DC Block, which is

simply a couple of one-way diodes to stop any DC voltage looping around in the

system. This dramatically reduces noise in your radio system.

To

make the DC Block, take a small block of marine ply to use as a base and coat

the whole thing in a couple of coats of epoxy to protect it from the elements.

Then take some copper foil long enough to cover one side and cut it in half.

Double it up if you like. Screw it down in place and solder the 2 diodes across

the 2 pieces of copper.

The

foil can be folded neatly to run through the boat but you should avoid

scrunching the foil. Staples are useful to hold it in place. Run duck tape over

the edges of the foil so that it doesn’t get damaged and also you won’t cut

yourself next time you have to work around the foil. Cover the rest of the

copper with a thin coat of paint or epoxy to keep it clean and un-tarnished. Do

not cut the foil unless you absolutely have to. There is always somewhere else

to run the foil. Don’t rush this part. Take your time and you will reap the

benefits.

The

best and only wire to use is GTO-15 cable. This wire may not look like much but

it is insulated and can carry 15000 volts. Always clean, solder and heat shrink

any connections.

You

will see the connection of the GTO-15 cable on the top of the tuner. Note the

heat shrink and the application of the Polyurethane Sealer paint. The other

important thing to notice is the Counterpoise wire. This is the black flat

plastic strip of wire with holes cut out of it. This runs from the tuner in the

lazarette all the way to the bow locker (about 75ft in total) and the radio

waves use this as a “Springboard” when you transmit giving you extra range

and a much clearer signal. The whole installation is finished by strapping all

the cables and wires down using cable ties and wire hold-downs (not shown here).

The

GTO-15 cable comes through the deck via a waterproof deck flange fitting and

runs up to the aerial of your choice.

There are 3 types of aerials you can have installed on

your yacht.

You

will see that we are currently using the halyard aerial. The connections are tin

soldered and heat shrunk after being covered with dialectic paste to prevent

corrosion. There is enough slack in the wires to trim off and re-connect if

necessary plus we carry spare GTO-15 cable.

A

good tip to avoid earthing your hard earned signal out to the un-insulated

backstay is to hold the wire off of the backstay using plastic tubing and cable

ties spaced every 2ft or so.

If

you decide to use the backstay aerial option, run the GTO-15 cable up the

backstay to immediately above the lower isolator (using the spacers every 2ft),

again soldering, coating in dialectic solution and heat shrinking the

connections. The wire can then simply be clamped to the backstay itself using a

hose clamp or jubilee clip. If you introduce a loop in the wire as shown above,

then any dampness will not be encouraged down to the connection itself but away

reducing corrosion even more.

To

finish off, wrap the whole kit and caboodle in self-amalgamating tape. Remember

that corrosion will quickly reduce the quality of any system installed on a

yacht so you should always endeavour to make any connections as good as possible

even if it does take extra time. You’ll be glad you did when you come to

service or replace parts.

This

photo taken from the stern looking up to the masthead, shows the halyard aerial

(on the right) attached to a topping lift. It can be quickly and simply dropped

and coiled when you don’t need it. I always drop and coil it away if there is

a risk of a lightening strike and disconnect the backstay aerial. You will

notice the isolator at the top of the backstay in a position to maximise the

range of the radio.

The

bottom of the halyard aerial is simply shackled to the pushpit through the eye

splice.

We

haven’t talked about the installation of additional counterpoise wires in your

installation as yet, so here goes. Your system will work without them but if you

can be bothered to put in the work, you will certainly reap the benefits.

What

is a counterpoise?

Basically

a counterpoise is a springboard for your radio transmission to “bounce off”

of into the atmosphere.

Good

grounding or counterpoise techniques are absolutely necessary for maximum single

sideband range.

Half

of your antenna is your radio frequency (RF) ground. The radiating portion of

your antenna needs to see a mirror image of itself before it will send out your

SSB signal.

This

mirror image (called a counterpoise) is created by using a metal surface and

seawater as your radio frequency ground plane.

Your

marine single sideband system will not perform satisfactorily if you don't have

a good counterpoise system. Poor counterpoise (ground) equals poor range. This

is especially true on lower frequencies where large RF grounds (counterpoise)

are required for good range.

Of

course, for those of you with aluminum hull vessels, your RF ground plane

(counterpoise) is your hull, and you'll probably have the loudest signal

anywhere in the world. No further RF grounding is necessary for you lucky

people.

As

an extra counterpoise (RF ground) to our ground plate and copper foil, we

decided to install additional wires, which connect to the same point as the

copper foil on your tuner. This then runs the entire length of the yacht right

up to the bow if possible.

A

capacitive ground system such as this, made up of copper foil run around the

hull below the water line, and individual copper strip wires at one-quarter

wavelength sections, is one way to achieve a very good ground.

The

wire we used was basically 2 wires separated by plastic (available at most

electrical shops). This allowed us to run two runs of cable at the same time. We

then removed a 1.5ft length from one side of one of the wires at 37ft down the

run from the tuner. These lengths correspond with the ¼ wave radial lengths

required to match the most commonly used frequencies in the marine industry.

After

all of this work, which took about a week to install completely, we popped

Talisman back in the water and started to see how she worked.

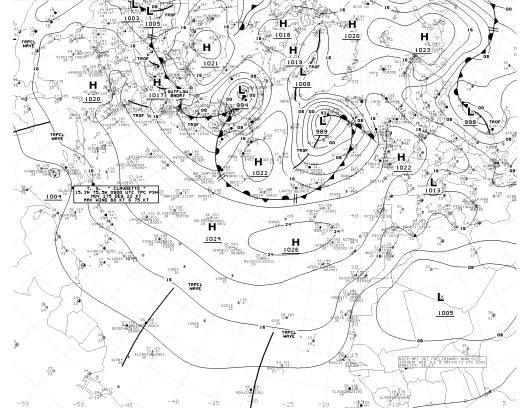

Here

is an image downloaded using “ICS Weather Fax” software on a laptop computer

connected to the audio out socket of the SSB radio.

As

you will see, the quality is excellent. And you can leave the software on

permanently to grab the broadcasts when they are made or set up a schedule to

download at the right times of day.

This

is the finished installed radio set hung from the shelf above. It’s easy to

use front end with large LCD display and positive feel knobs makes using it a

pleasure.

The

Pactor PTC-II Pro is an excellent addition to the radio set for email and

Internet access.

The

connections are simple and it’s powered by the SSB radio itself. Note the

graphite insulators that the wires are run through. These reduce noise and

interference even more.

I

hope that this helps you install or re-install your SSB system so that you start

to see the same results that I did.

I

am a fully qualified MCA Class 4 Master of yachts and have been running yachts

professionally for 6 years, having started playing in boats at the age of 6.

I

have a lot to offer and if I can help you further, maybe with sourcing and

sizing a halyard or backstay aerial, or your counterpoise, just drop me a line.

You will find me through my web site at www.crew4sail.com

Follow the “Contact Us” link.

Here

are some additional areas you can look at if needed, to reinforce your knowledge

and resources:

www.boatfix.com

link for WonderBar grounding plates

http://www.marinco2.com

link for the Dynaplate grounding plates

http://www.sailnet.com/collections/articles/index.cfm?articleid=suelar0175

A good article on Single Sideband Radios

http://icomamerica.com/

ICOM’s web site.

http://www.atomvoyages.com/AerialTricks.htm

A good source of information on antennas